Lithium-ion batteries are everywhere: from smartphones and laptops to cars and even satellites. It is currently our most mature battery technology. However, it is not ideal for many applications. Lithium-ion batteries lose capacity with every charge and discharge cycle, charge relatively slowly and only work well in a narrow temperature range.

According to Empa researchers Abdessalem Aribia and Moritz Futscher from Empa’s Thin Films and Photovoltaics laboratory, it is time to rethink battery technology. Compared to other existing or developing technologies, their lithium metal-based solid-state battery brings some significant advantages: It can be charged and discharged within one minute, lasts about 10 times as long as a lithium-ion battery, and temperature fluctuations don’t affect it.

In addition, unlike lithium-ion batteries, it is not flammable – a major advantage, because today’s rechargeable batteries are considered hazardous materials. Incorrect handling or damage to a conventional lithium-ion cell can lead to a fire that releases toxic gases and is extremely difficult to extinguish.

“By contrast, if you cut our battery with scissors, you will simply get two batteries that are half as good!” Aribia said.

Aribia and Futscher now want to bring the technology to market. Together with lab head Yaroslav Romanyuk, they have founded a spin-off called BTRY (pronounced battery). Aribia, who takes on the role of CTO at BTRY, had never previously thought of starting his own company. CEO Moritz Futscher, on the other hand, has been interested in startups since he was a student.

High-precision manufacturing

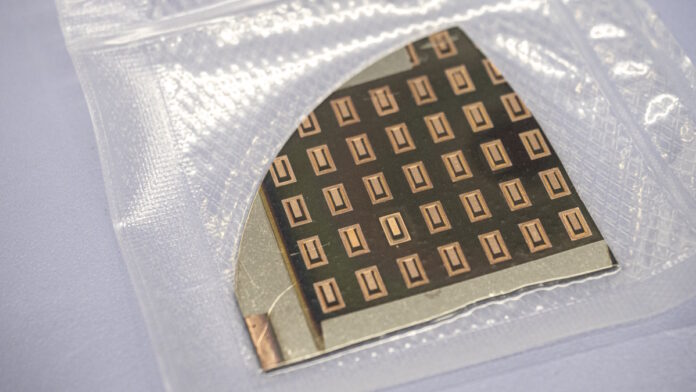

The new battery is a thin-film solid-state battery. The technology itself is not new: Such batteries have been known since the 1980s. However, due to the very low mass of their thin-film components – the entire cell is only a few micrometres thick – they have been able to store very little energy so far. Futscher and Aribia have succeeded in stacking the thin-film cells on top of each other, increasing their capacity.

This makes the battery promising for commercial applications. The thin-film cells are manufactured using vacuum coating: The desired materials are atomized in a vacuum chamber to form individual atoms, which are then deposited in a precisely controlled layer on the target substrate.

“Such manufacturing methods are currently used on a large scale in the production of semiconductor chips and glass coatings,” Futscher said.

“That’s an advantage for us, because the machines and know-how to manufacture our battery are largely in place already.”

The high-precision manufacturing method has an additional advantage.

“In contrast to the traditional method of battery production, our method does not use toxic solvents,” Aribia said.

However, it also makes the thin-film battery more expensive. The researchers therefore see its application primarily in products where the battery only accounts for a small part of the overall cost of the device – for example, in smartphones and smartwatches or in satellites.

“There, the advantages of our technology more than make up for the higher price,” Aribia added.

Investors sought

The researchers are not the only ones who believe their product has a lot of potential. BTRY was supported by Innosuisse and made it into the business incubator of the European Space Agency (ESA). In addition, Aribia received an Empa Entrepreneur Fellowship, which supports young researchers who want to start a company.

But before the first thin-film batteries launch into space or supply smartphones with electricity, there is still a lot to do, both on the administrative and on the technical side. In the meantime, the two founders are using Empa’s Coating Competence Center to create bigger and more powerful battery prototypes to show potential investors the technology is worth backing.

Over the next two years, the researchers want to increase both the surface area of the battery and the number of layers.

“Currently, our batteries consist of only two layers of about 1×3 millimetres,” Aribia said.

“Next, we want to make a battery of about one square centimetre with two to three layers. We can’t power a satellite with that yet – but we can very well show that our technology is scalable.”

Jim Cornall is editor of Deeptech Digest and publisher at Ayr Coastal Media. He is an award-winning writer, editor, photographer, broadcaster, designer and author. Contact Jim here.